Solvent resistant and heat resistant solvent distillation bag - RECBAG

For use in distillation plants for solvent recovery - and for further applications

DISTILLERS - SOLVENT RECOVERY

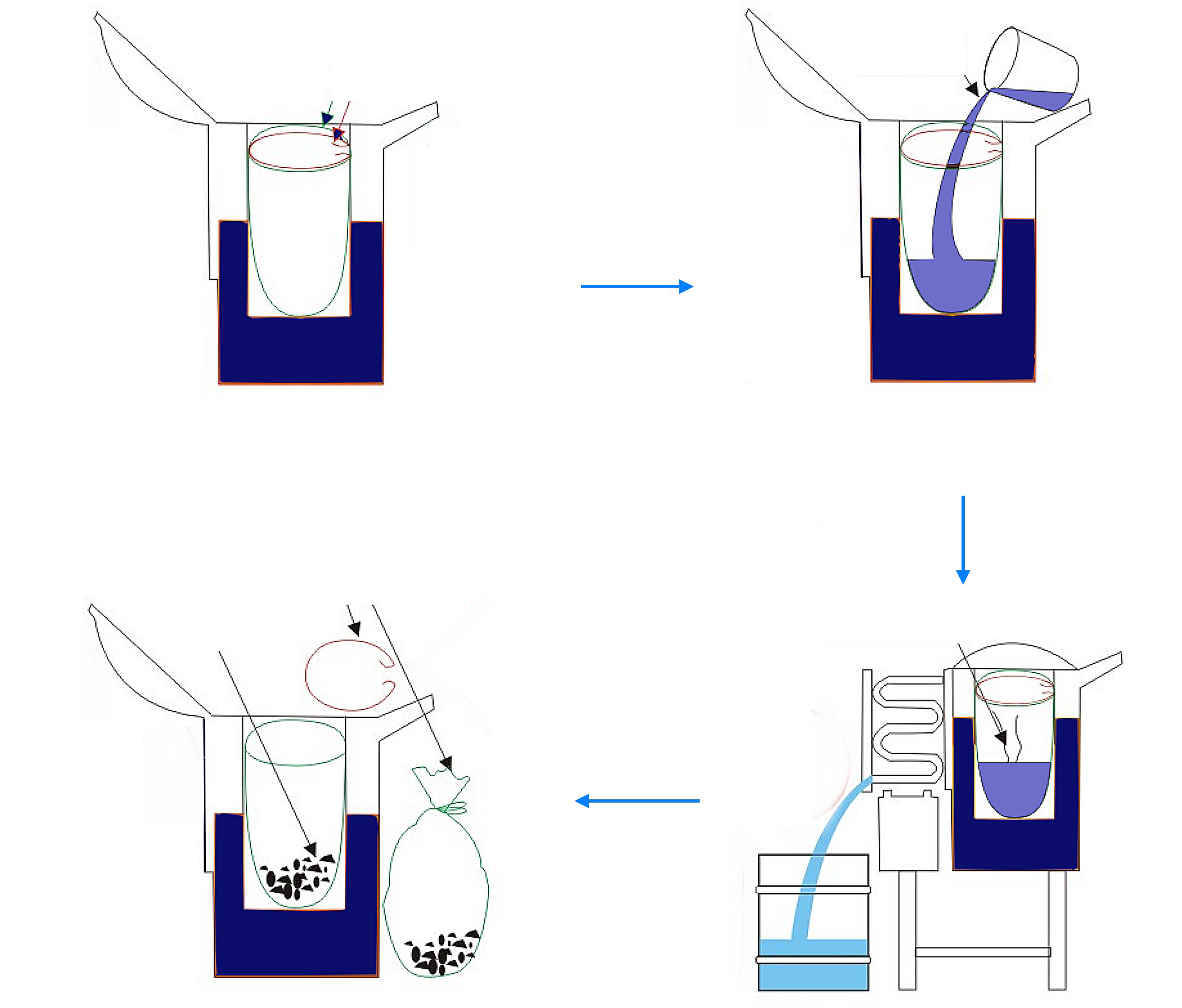

Easy removal of the distillation residue

Distillation enables the recovery and reuse of contaminated solvents in many areas. During the distillation process contaminants (resins, polymers, pigments, varnishes, oils, etc.) are separated from the original solvent. The solvent properties are not changed by distillation, so the process can be repeated as often as required. The contaminants remain in the boiling vessel of the distillation unit. To avoid time-consuming cleaning work, the heat-resistant and solvent-resistant RECBAGS can be inserted into the boiling vessel and disposed of properly with the residues after completion of the distillation process. Thus, the RECBAGS allow a safe, economical and - last but not least - ecologically sensible handling of problematic working substances.

PAINTING TECHNOLOGY - RESIDUAL POWDER DISPOSAL

Easy disposal of remainder powder (ex. surface coating)

The time-consuming disposal of powder dust is made considerably easier and disposal costs are reduced by using our heat-resistant foil bags.

Fill residual powder into the bag -> melt in the oven -> dispose of properly

In the CHEMICAL INDUSTRY there are countless applications for the film bags that are resistant to high temperatures and many chemicals and solvents, but there are also almost no limits to their use in other areas. RECBAGS can be used almost everywhere where problematic substances have to be stored, protected or disposed of.